“In the past few years, CFD has become very important to us, especially in helping us to design products that meet and exceed the requirements on new emissions regulations.” says Dupon. “Before the arrival of CFD, we had no choice but to rely on experimental testing, and a process of trial and error. Our success in those days relied heavily on the experience of our engineering team, with product development driven as much by engineering intuition as hard data.” Dupon remembers. “Although this process delivered some excellent products, the cost of making a wrong design decision that would only be exposed by testing late in the cycle was very high. CFD allows us to mediate that risk through building virtual prototypes early in the design process.”

However, before CFD could be considered as a serious alternative to physical testing, it first had to overcome credibility issues: “When we started using CFD a decade ago, people were not confident in its capabilities or in the accuracy of its results. They would tell us: ‘We can do this faster in experiment than you can do in your simulation.’, ‘You have to estimate your parameters.’ or even ‘You don’t know what you are doing.'”, says Dupon before adding with a smile, “No doubt, in the very early days, they were often right. However, by consistently delivering high quality results that correlated well with experiments, we managed to gradually challenge that perception. Today the mood is rather different, and there is real belief in the power of engineering simulation.”

Despite this obvious success, both Dupon and Platteeuw are anxious to point out that CFD has not replaced physical testing in the Off-Highway product development process: “CFD and experimental testing are complementary tools, they work best when used together. At CNH Industrial, we continue to correlate our CFD models against data from physical tests to make sure that we can continue to be confident in our future simulation results. I firmly believe that testing and CFD will always go together.”

“You have to see how the product performs out in the field.” adds Platteeuw. “In our case, that literally means ‘standing in the field’, as we have to understand the role that weather, terrain and crop type have on our CFD models. In order to properly simulate the physics, we have to understand all the boundary conditions, especially as the demands of the commercial vehicle industry constantly drive us to using bigger, more complex models that more accurately capture all the relevant physics.”

In pushing back the frontiers of commercial vehicle simulation, CNH Industrial enjoys a close working relationship with CD-adapco.

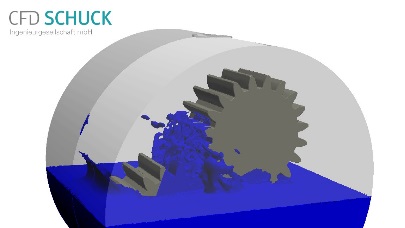

“We have a very good relationship with our Dedicated Support Engineer (DSE), who has worked closely with us to understand our applications and the many ways in which CD-adapco’s tools can help us meet the engineering challenges that we face.”, says Platteeuw, “One example of this is the way that we have used the unique coupled DEM capability of STAR-CCM+ to directly model crop processing and management. We are also working closely with our DSE to implement overset meshes into our process.”

In just over ten years, CFD simulation has evolved from being an ‘interesting curiosity’ to occupying a central role in the commercial vehicle development process: “We cannot imagine a world without CFD here in product development. There is no way back!” confirms Dupon.

More around this topic...

In the same section

© HPC Today 2024 - All rights reserved.

Thank you for reading HPC Today.