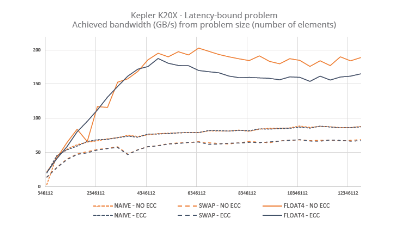

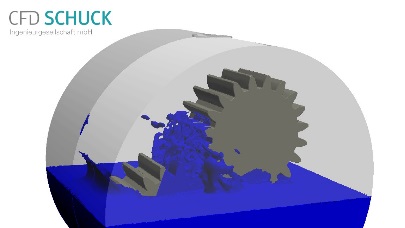

Researchers use TACC supercomputers to perform simulations of orbital debris impacts on spacecraft and fragment impacts on body armor. These simulations are evaluated at up to 10 kilometers per second to ensure that they accurately capture the dynamics of hypervelocity impacts and match real-world experiments conducted by NASA.

Aaron Dubrow

We know it’s out there, debris from 50 years of space exploration — aluminum, steel, nylon, even liquid sodium from Russian satellites — orbiting around the Earth and posing a danger to manned and unmanned spacecraft. According to NASA, there are more than 21,000 pieces of “space junk” roughly the size of a baseball (larger than 4 inches or 10 centimeters) in orbit, and about 500,000 pieces that are golf ball-sized (between 0.4 inch to 4 inches or 1 to 10 centimeters). Sure, space is big, but when a piece of space junk strikes a spacecraft, the collision occurs at a velocity of 3.1 to 9.3 mph (5 to 15 kilometers) per second—roughly ten times faster than a speeding bullet!

“If a spacecraft is hit by orbital debris, it may damage the thermal protection system,” warns Eric Fahrenthold, professor of mechanical engineering at The University of Texas at Austin, who studies impact dynamics both experimentally and through numerical simulations. “Even if the impact is not on the main heat shield, it may still adversely affect the spacecraft. The thermal researchers take the results of impact research and assess the effect of a certain impact, crater depth and volume on the survivability of a spacecraft during reentry.”

Only some of the collisions that may occur in low earth orbit can be reproduced in the laboratory. To determine the potential impact of fast-moving orbital debris on spacecraft — and to assist NASA in the design of shielding that can withstand hypervelocity impacts — Fahrenthold and his team developed a numerical algorithm that simulates the shock physics of orbital debris particles striking the layers of Kevlar, metal, and fiberglass that make up a space vehicle’s outer defenses.

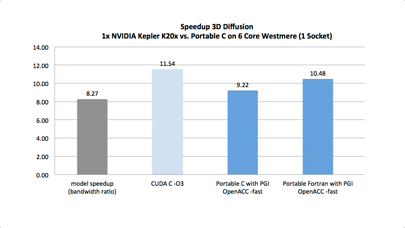

Supercomputers enable researchers to investigate physical phenomenon that cannot be duplicated in the laboratory, either because they are too large, small, dangerous — or in this case, too fast — to reproduce with current testing technology. Running hundreds of simulations on the Ranger, Lonestar and Stampede machines at the Texas Advanced Computing Center, Fahrenthold and his students have assisted NASA in the development of ballistic limit curves that predict whether a shield will be perforated when hit by a projectile of a given size and speed. NASA uses ballistic limit curves in the design and risk analysis of current and future spacecraft.

Results from some of his group’s impact dynamics research were presented at the April 2013 meeting of the American Institute for Aeronautics and Astronautics (AIAA), and have recently been published in the journals Smart Materials and Structures and International Journal for Numerical Methods in Engineering. In the paper presented at the AIAA conference, they showed in detail how different characteristics of a hypervelocity collision, such as the speed, impact angle and size of the debris, could affect the depth of the cavity produced in ceramic tile thermal protection systems. The development of these models is not just a shot in the dark. Fahrenthold’s simulations have been tested exhaustively against real-world experiments conducted by NASA, which uses light gas guns to launch centimeter-size projectiles at speeds up to 10 kilometers per second. The simulations are evaluated in this speed regime to ensure that they accurately capture the dynamics of hypervelocity impacts.

Validated simulation methods can then be used to estimate impact damage at velocities outside the experimental range, and also to investigate detailed physics that may be difficult to capture using flash x-ray images of experiments. The simulation framework that Fahrenthold and his team developed employs a hybrid modeling approach that captures both the fragmentation of the projectiles — their tendency to break into small shards that need to be caught — and the shock response of the target, which is subjected to severe thermal and mechanical loads.

“We validate our method in the velocity regime where experiments can be performed, then we run simulations at higher velocities, to estimate what we think will happen at higher velocities,” Fahrenthold explains. “There are certain things you can do in simulation and certain things you can do in experiment. When they work together, that’s a big advantage for the design engineer.”

More around this topic...

© HPC Today 2024 - All rights reserved.

Thank you for reading HPC Today.