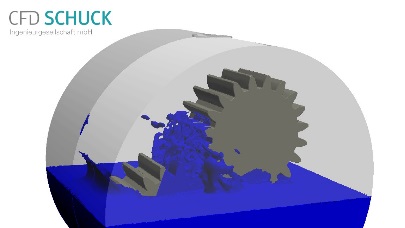

Despite this success, the most significant combustion problem of all, that of the automobile engine, remained unaddressed. Unlike other combustion problems, engine flow combustion processes are non-stationary; taking place in a solution domain that has a complex geometry and moving boundaries. The accurate simulation of engine combustion would also require the development of multi-phase models to account for fuel-sprays and films, as well as ignition, combustion and turbulence models. Of course, considering the unsteady nature of the problem, the complex physics and the large mesh sizes required, the solution of engine combustion problems also required the development of a robust and efficient solution algorithm to perform the large number of time-steps necessary to achieve a credible solution using the limited computing resources available.

Prof. Gosman published the first axisymmetric CFD simulation of cold flow in a reciprocating engine in 1978[5], before dedicating much of the next decade to developing the techniques that would allow the simulation of a fully-detailed engine combustion process in three-dimensions. To account for the movement of pistons and valves, he developed a novel Eulerian-Lagrangian moving mesh methodology, which eventually included cell-layer addition and removal to prevent numerical problems that can occur in high aspect ratio cells. In the field of fuel spray modeling, he also co-developed the Huh-Gosman model for spray atomization and the Gosman-Bai model for wall impingement. To address time-step and stability concerns, Prof. Gosman implemented the non-iterative PISO algorithm developed by Imperial colleague Dr Raad Issa, which allowed the computationally efficient solution of unsteady compressible flows using relatively large time-steps.

The combination of this work, with many other developments, resulted in the CFD code SPEED, which was developed as a semi-commercial collaboration between Prof. Gosman’s Imperial team and a number of industrial partners.

Prof. Gosman’s other significant research interest was in developing simulation methodologies that could cope with the complex geometries of real engineering problems. The commercial CFD codes of the time relied almost entirely on fully structured cartesian computational grids, which dealt with complexity using a crude “stair-step” approach, which in effect led to large inaccuracies in any geometry that could not be represented as a combination of cylinders and boxes. A decade spent trying to model the geometries of complex engine combustion chambers and induction systems had convinced Gosman of the need to develop a more robust methodology for simulation using body-fitted meshes, not just for engines, but also for all types of industrial CFD problems. He therefore set out to systematically find a way of producing flexible mesh methodology that would fit all geometries, however complex. After significant investigation of many alternatives, he finally settled on an approach based on co-located Cartesian velocities inspired by work of Rhie and Chow and then generalized this to partially and then fully unstructured CFD meshes, including those with sliding interfaces.

By the middle of 1980s Prof. Gosman’s team had assembled a formidable set of simulation tools, many of which were far in advance of the commercial CFD codes that had begun to emerge, particularly in the field of complex geometry handling. The experience of testing and supporting SPEED had convinced Prof. Gosman that academia was not an ideal environment from which to develop a CFD code and so, together with Dr Raad Issa, he formed Computational Dynamics Ltd as a commercial venture, with the aim of developing an unstructured body-fitted industrial CFD code.

More around this topic...

In the same section

© HPC Today 2024 - All rights reserved.

Thank you for reading HPC Today.

Most read articles