Traditionally synonymous with inaccuracy in the simulation of fluid flows, turbulence phenomena are now globally harnessed by major CFD solutions. The question that remains is which, among the new models they propose, is best suited to your application requirements and available computing resources…

Gilles Eggenspieler, Ph.D – Senior Product Manager, ANSYS

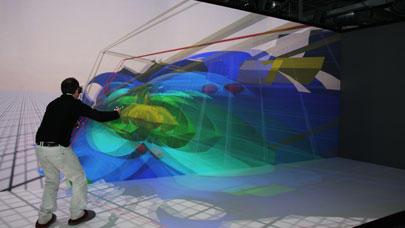

Turbulence plays an important role in the vast majority of industrial fluid flow applications. It constitutes a classic multiscale problem in which turbulent flow structures of many different scales interact with each other. Accurate prediction of a system’s aerodynamics, heat transfer characteristics, mixing performance and other factors is key to determining performance with high precision – to the point that accurate and robust turbulent modeling capabilities are critical in computational fluid dynamics (CFD). Resolving all turbulent flow scales present in industrial applications via simulation is not possible with today’s computational resources, but formulations can be used that reduce a problem’s complexity while still delivering accurate information on flow turbulence and its effect on product performance.

Because turbulence is a very complex phenomenon, no single do-it-all formulation has been found to date. There are so many turbulence models in existence that the challenge for CFD software developers is to incorporate the right subset of models, resulting in a package that is robust, accurate and validated – and that covers applications that users need. Leaders in the field don’t stop there; they offer best practices so a user knows which model to use for a specific turbulence problem. They also advance physics by innovating, testing and validating new hybrid and transition models that deliver the best mix of accuracy and computational intensity for today’s challenging applications.

Turbulence Simulation Challenges

Most engineering flows are turbulent, and these flows are inherently multiscale, three-dimensional and unsteady. Fluid flow applications involving complicated geometries and complex physics present the greatest challenges from a turbulence-modeling standpoint, particularly in the industries listed below.

Aerospace – Accurate turbulence modeling is critical to major aerospace challenges such as optimizing lift/drag ratio of a wing to ensure that the plane will fly safely while consuming as little fuel as possible. Turbulence modeling is involved in many other aerospace design problems, such as designing the engine to minimize both external and cabin noise.

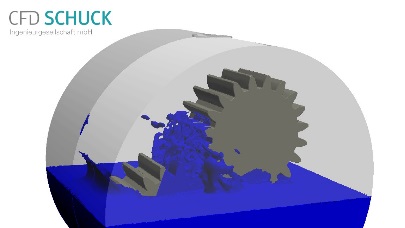

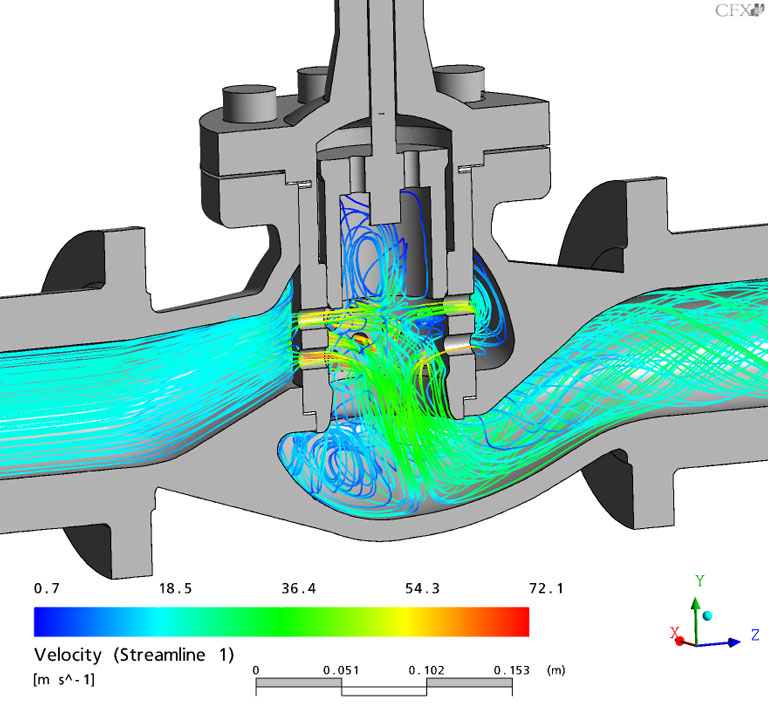

Accurately predicting the performance of a complex valve system requires turbulence models that can capture flow characteristics in both the large main pipe and the small openings. Wall effects, which generate a large amount of turbulence, need to be captured as well.

Oil and Gas – Turbulence dissipates flow energy, so turbulence modeling is critical for companies involved in moving fluids over long distances. For example, it is important to accurately predict energy loss to determine the optimal distance between pumping stations. If the distance is too large, the flow moves too slowly or even stops flowing. If the distance is too small, the pumping system is overdesigned and under-optimized, leading to higher- than-necessary pump installation, operation and maintenance costs. The ability to accurately predict flow behavior and pressure drop induced by turbulence helps companies to design the most efficient and cost-effective oil and gas transport systems.

Car manufacturers rely on accurate computational fluid dynamics of turbulent flows to compute the cooling and heating of a passenger car.

Automotive – Automotive aerodynamics is all about trade-offs, particularly striking the right balance between body style needs and aerodynamic concerns. Predicting the drag of alternative designs is the key to delivering an appealing design that is as fuel efficient as possible. Turbulence dictates a design’s aerodynamic performance, so accurate prediction of a design’s drag requires accurate, tested and validated turbulence models.

Chemical and Pharmaceutical – Mixing is a crucial step in most chemical and pharmaceutical industry processes. The throughput of many process operations depends on achieving homogeneous mixing in as short a time as possible. Designers of mixing equipment utilize CFD to evaluate alternative agitator and tank designs and operating conditions to determine optimal configuration. Turbulence plays a critical role in mixing, so accurate turbulence modeling is essential to getting the design right the first time.

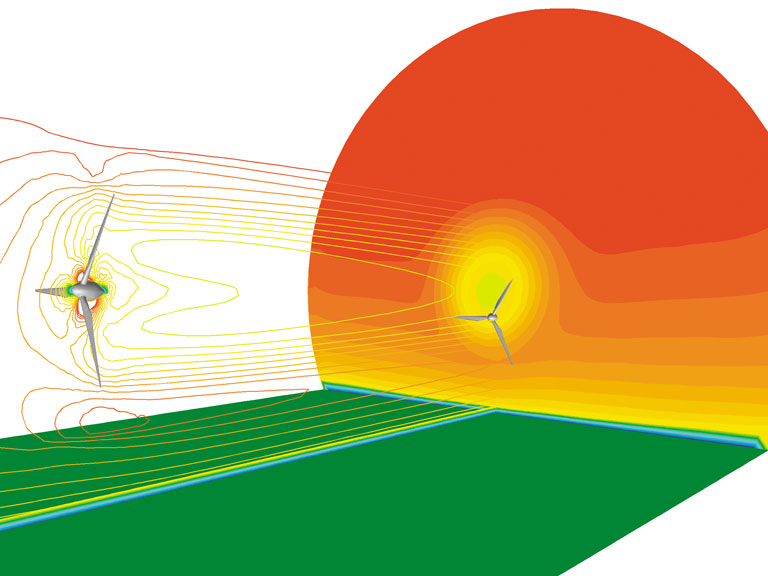

Green Energies – For power companies that operate wind turbines, the goal is to generate the maximum amount of power at the lowest cost from a given wind farm site. The challenge is that the wake of a turbine has significant effects — including reduced power output and shorter turbine life — for units located downwind. Wind farm developers are demanding more accurate methods for calculating these wakes as well as any terrain effects that impact a turbine’s performance. By accurately predicting these phenomena, power companies can optimally place each wind turbine to produce maximum energy from a given parcel of land.

More around this topic...

In the same section

© HPC Today 2024 - All rights reserved.

Thank you for reading HPC Today.