The latest competition cycle helmet from Louis Garneau, a specialist in top-flight sports equipment, was designed entirely using engineering simulation. The results are convincing, both in racing and financial terms…

Perhaps more than any other sport, competitive cycling is dominated by aerodynamics, as cyclists, clad in aerodynamic clothing and helmets, are forced to adopt uncomfortable crouched position on their bikes to minimize their frontal area and reduce their exposure to the oncoming air. This is most apparent in Individual Time Trial (ITT), which is a key component of triathlon, track and road races. With no other riders to draft behind, the ITT is known as “the race of truth”, a brutal contest of man and machine against the clock. Consequently, for around 25 years, professionals have worn specially-designed helmets in order to guide the air around the head and prevent gross separation behind what would otherwise be a bluff body – giving real gains in speed for a given power output.

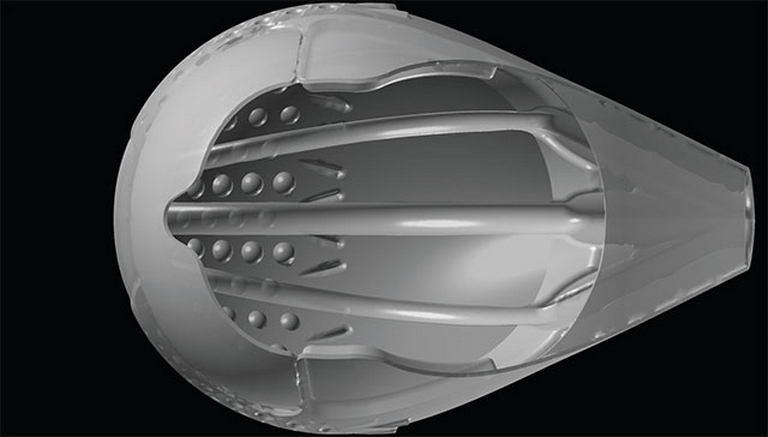

Year on year, cycling helmets have been the subject of much engineering attention, with the aim of further reducing the drag signature of the rider. To be successful, an aero-helmet also has to be properly ventilated (preventing the rider from overheating at maximum effort), impact resistant (protecting the rider’s head in the event of a crash), and constructed from lightweight materials. Determined to address these inherently complex problems as a whole and as innovatively as possible, Louis Garneau turned to engineering simulation, which now plays a leading role in all the company’s design and manufacturing processes.

Front runner

Louis Garneau is one of the leading quality sports equipment manufacturers. Its founder and CEO – after whom the company is named – was himself a cycling champion, with over 150 victories over thirteen years, in both road and track events. He represented Canada at the Los Angeles Olympics in 1984.

The first Louis Garneau branded helmet, Prologue, appeared in 2002. It was a revolutionary product, combining aerodynamic streamlining with impact protection. Until then, time trial helmets were basically just head-mounted aerodynamic fairings that offered no protection in the event of a fall. Thanks to its innovative features, Prologue was the first aero-helmet to attain certification to the US CPSC (Consumer Product Safety Commission) bicycle helmet standard, meaning that it was also the first aero-helmet that could legally be sold to the general public. Two years after the arrival of Prologue, cycling’s governing body, the UCI, introduced a law stating that all helmets used in competition must meet the less stringent European EN 1078 bicycle helmet safety standard.

From traditional to digital

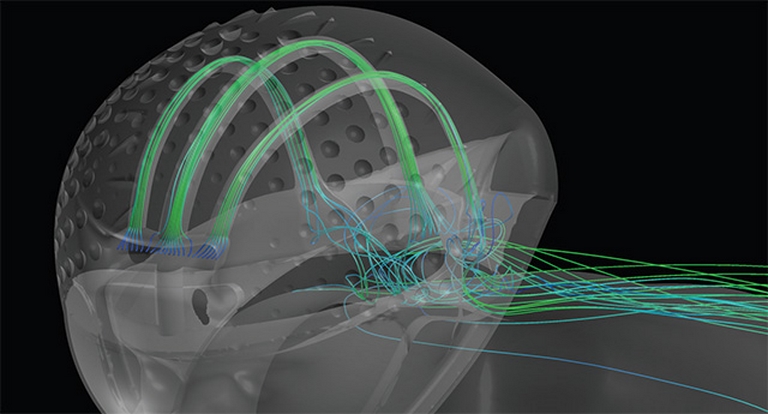

Through four subsequent iterations (Prologue in 2004, Rocket in 2006, Rocket Air in 2007, and Superleggera in 2008), Louis Garneau continued to advance their professional helmet line, with each new helmet design painstakingly engineered using a traditional design-build-test approach. For each design iteration, it was necessary to create a clay model, tool the production line to make a prototype helmet and perform wind tunnel tests before taking the helmet to market. Making changes after prototyping was difficult, due to the cost and time required to retool the production line. In a competition context, time is especially important, considering that the helmets must be manufactured and shipped in time for set racing days. Although it was the only practical solution at the time, wind tunnel testing, due to inherent physical limitations, was an imperfect way to measure air flow, especially inside the helmet where air channels are cut to help cool a cyclist’s head and around really small features, such as the dimples on Superleggera, whose exact effects were very much unknown.

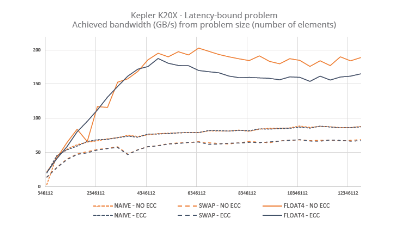

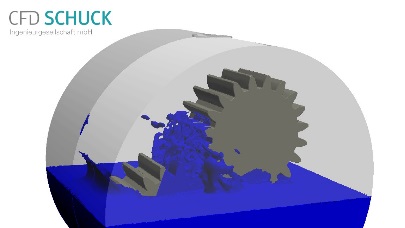

To get a better understanding of the detailed aerodynamics of their helmets, Louis Garneau approached Lx Research & Development, a mechanical engineering consulting firm that specializes in engineering simulation and product development. To begin integrating CFD (computational fluid dynamics) into the design process, and to demonstrate the concept to Louis Garneau, Lx Research & Development began by scanning a 3-D model of Superleggera and a cyclist to analyze. This required separate scans, which were then merged together digitally to reproduce Louis Garneau’s wind tunnel model. The resulting CFD analysis of this model, using the STAR-CCM+ software package developed by CD-adapco, came within 4% of Louis Garneau’s own analysis during the wind tunnel test, thus verifying the results found by Lx Research & Development. This was enough to ensure that Louis Garneau adopted the proposed methodology.

More around this topic...

In the same section

© HPC Today 2024 - All rights reserved.

Thank you for reading HPC Today.