35 years ago, three young engineers started an engineering simulation business. Their intention was to apply the numerical simulation technology that was beginning to emerge from the nuclear industry to the wider set of engineering problems faced by industry as a whole. Those three engineers were Steve MacDonald, Bill Wheeler, and Marc Whittlesey and the company that they formed was adapco (a company that would eventually become CD-adapco). I recently met up with them at the company headquarters in New York, with the aim of discovering how the company got started.

BEGINNINGS

adapco was born, almost fully formed, out of the Nuclear Industry, which in the late 60s had begun to employ numerical simulation as a tool for understanding some of the structural issues involved in designing nuclear power plants. Of the three founders, Steve MacDonald was the first to immerse himself in this brave new world of simulation. Graduating in 1967 with a degree in Engineering Physics, from the Colorado School of Mines, he was originally employed by Bettis Atomic Power Laboratory, which was operated by Westinghouse for the Department of Defense, to perform physical testing. “I was supposed to be working on the fatigue testing of materials, but the group that did that were also beginning to get their hands dirty with simulation, so pretty soon I ended up getting involved in that,” recalls Steve MacDonald.

Immediately seeing the opportunity, Steve MacDonald enrolled himself in Carnegie Mellon University at night and began using FEA tools in his job – initially a 2D FEA code called “FEAT”, and later 3D tools that were developed by his own lab. “I got involved in simulation early and did a lot of application development and I worked there for almost five years. I went to night school to get a masters degree. I did all my coursework for a PhD but didn’t finish my thesis’.

In the next few years, rather than pursuing an career in academia, Steve MacDonald began to use the tools at a succession of engineering companies around the Nuclear Industry, finally becoming an engineering supervisor for the FEA team at EDS Nuclear in Long Island, which he describes as “an extremely aggressive nuclear consulting company business that was entirely focused on generating profit”.

Into this team, Steve MacDonald recruited two engineers. Texan Bill Wheeler, a graduate of Texas A&M and Carnegie Mellon, who had previously worked for MacDonald Douglas and Westinghouse, and Marc Whittlesey, a graduate of Iowa State University, who had worked with MacDonald for three years at Foster Wheeler. Almost immediately, MacDonald, Wheeler and Whittlesey began to increase the scope of the engineering simulation employed by EDS.

“We were doing finite element analysis for the nuclear power industry,” says Bill Wheeler. “That was the primary business of the company. They had their own piping stress code, and they were doing lots and lots of piping stress analysis, although we didn’t get much involved with that. Steve had lots of connections from his previous jobs so we ended up working on steam generators, pressure vessels, and things like that. It was a fairly lucrative business because there was a federal law that said you had to do analysis of all the safety related equipment in a nuclear power plant. So, there was a lot of that kind of work being done, trying to show that components were going to hold up to all the postulated operating conditions and accidents without failing.”

THREE MILE ISLAND

In 1979, the bottom fell out of the Nuclear Industry as a result of the “Three Mile Island” accident, in which one of the two Three Mile Island nuclear reactors in Dauphin County, Pennsylvania, suffered a partial meltdown. It was the worst accident in US commercial nuclear power plant history, and ultimately led to the cancellation of 51 US nuclear reactors that were planned to be built from 1980 to 1984.

“Steve and I were on a plane going to Pittsburgh to talk to some people at Westinghouse,” recalls Bill Wheeler. “And when we landed, we heard about the Three Mile Island accident. And we both just said, ‘That’s going to burst this bubble we’ve been working in.’”

“Steve convinced the company we were working for, EDS Nuclear, that maybe they should broaden their horizons with the gloomy outlook of the nuclear power industry,” continues Bill Wheeler. “EDS gave us a charter for about a year to try to work non-nuclear programs. Steve managed to somehow land us some contracts, with General Electric Aircraft Engines in particular, where we started working on fairly sophisticated three-dimensional finite element analysis of some bolted joints they were having problems with.”

“We did that for about a year, which really taught us how to run a company,” remembers Marc Whittlesey, “Steve, Bill and I had numerous discussions about doing exactly that, because were doing budgets and planning and manpower and all this kind of stuff and so there was really very little about running a company that we didn’t know how to do.”

MacDonald, Wheeler and Whittlesey began formulating plans to start their own engineering services business sometime in 1981. However, they were forced to put those plans into action rather more quickly when the EDS management got wind of them. “We formed our company, went down and took out the name and everything, so we actually had a company before we left,” says Steve MacDonald. “And, of course, me being a person who tended to open his mouth too much, and still does, I’d talk about it to people. Word got back to the management of EDS Nuclear.”

“The three of us were in Napa Valley at a training session for this large 1,000-man company, and we were terminated,” continues Steve MacDonald. “Which was interesting because I had a wife and three kids and I had a mortgage, as did Marc and Bill, and so it was time for us to go to work. So we were pushed out maybe a little early. We were probably going to go anyway three months later.”

“The thing that I remember is that when we left EDS Nuclear, they had about 900 people in the United States doing piping support stress analysis,” says Bill Wheeler. “By 1982, they had zero. So, it wasn’t that we were visionaries about forming a business. It was kind of a necessity. I think we all understood we had to do something because the nuclear bubble had burst. That was very obvious to all of us.”

THE BIRTH OF ADAPCO

So, from the embers of the Nuclear Industry, adapco was born, initially as a four person outfit (the fourth person was Joe Sklerin, a minority shareholder in the original business) that operated out of Bill Wheeler’s attic in Long Island.

“We actually incorporated a company in the late summer of 1980,” remembers Bill Wheeler. ”The company name, Analysis and Design Application Company, was about our fourth or fifth choice. I don’t remember what the first few choices were. But the New York state government said they were too close to somebody else’s name and wouldn’t let us have that. So, we wound up using Analysis and Design Application Company Limited, and abbreviated to adapco. That’s really where we got the name, it wasn’t Steve’s first choice.”

“It was also obvious that there was only going to be one person who was electable as president. And that was Steve”, says Bill Wheeler. “If anybody knew him, they would know instantly that he was the only choice. Steve is a natural leader, he had the unique ability to communicate and convince people to give him whatever he needed. That was his really strong point. He was also a very, very technically savvy engineer. But I’m not sure that he had the patience that Mark and I had to work a problem.”

Steve MacDonald agrees: “Well, I always say that I wanted to be the president and I worked long enough to know that I would never make president in a highly structured company, so my solution to that was to go form my own company and appoint myself. That was the solution to my personal dislike of authority. Anyway, so I thought, well, I’ll just start a company. That’s how it happened. I did a lot of things that turned out to be good enough so that we didn’t go out of business.” “The three of us had things that we each brought to the mix,” says Marc Whittlesey. “Steve was the ideas guy, the guy that liked to meet with the customers, go out, sell the work, that became very apparent right from the get-go. Bill Wheeler was the ultimate technocrat, he was always looking for the best way to skin the cat and so forth, and I was kinda the do-er, the guy that was really good at getting simulations running, and the results out of the door.”

“So, that mix tended to work fairly well and it kept us out of technical trouble,” remembers Marc Whittlesey. “Of course Steve’s focus was on getting the work and thinking of the new methods and of course that caused me a lot of consternation at times, when he would sell something based on a promise and we had no idea how to do this and it would drop on my desk. But that’s what makes you smart, you know, it gives you a challenge. Something that you didn’t know how to do at the time but you knew you had to get done in a limited amount of time and that ‘Necessity really is the mother of invention’.”

PHILOSOPHY OF SUCCESS

This “pushing the boundaries” is a common theme. A large part of adapco’s (and later CD-adapco’s) success is based upon the principle that, right from the very beginning, Steve MacDonald realized the solution of real world engineering problems, which usually involve the interaction of many different physical phenomena, would ultimately require simulation tools that spanned a range of engineering disciplines.

“When performing numerical simulation you need boundary conditions,” says Steve MacDonald. “If you get your boundary conditions wrong, then you’re in trouble. So if you take an isolated component or area, let’s say, the problem is that you are very dependent upon having exactly the right boundary conditions there or you’re not going to get the right answers from your simulation. So my philosophy from the beginning was to model as far away from the object as I could get practically because then, even though I may not know the boundary conditions perfectly, I have a chance for the boundary conditions to adjust to a degree, some of them anyway, before the solution had propagated to the component that I was looking at.”

“That was our philosophy,” agrees Wheeler. “We’re going to use as big a computing system as we could possibly fi nd or afford. And we’re going to put as much detail and not make assumptions any more than we absolutely had to. That was the guiding principle from the day we started the company. I think that’s probably still refl ective of the company overall today. We were not trying to use our experience to make the analysis tell us what our experience says. We were trying to get the analysis to tell us what was really happening and use our experience to try to debug our analysis work.“

“One of the first jobs was from Solar Turbines,” remembers Steve MacDonald. “Another was from General Electric, Lynn, which was the small aircraft engine division of GE. We got a remote job entry terminal, which was a card reader and a printer, and we prepared our problems. Then a little bit later, we bought a computer, which was about the size of a washing machine, it was a VAX 750, and we used that along with some discs. And, again, we were doing stress and thermal analysis, mainly, and a lot of it was on gas turbines, things that had thermal stress in them and were important.”

“And we moved into this building, we went from working in Bill Wheeler’s attic for a very short period of time to renting one-half of the bottom floor of this building at that time, and then we rented the whole bottom floor and then we rented the first floor. Eventually we ended up buying the whole thing. We just kept growing”, says Steve MacDonald.

FROM STRESS TO CFD

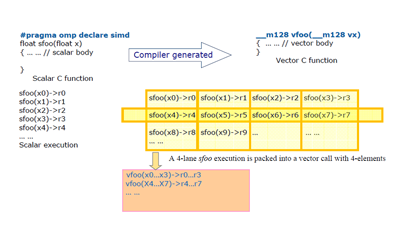

Up until this point, adapco had been almost entirely involved with Finite Element Analysis of thermal and mechanical stress. However, Steve MacDonald’s vision of “pushing the boundary conditions as far away as possible from the region of interest”, began to necessitate the use of other simulation tools. “I remember Steve coming back from some of the meetings he was having with Ford where we were doing some heat transfer analysis,” says Bill Wheeler. “We didn’t know what the heat transfer coefficients were, but they could tell us how much the total heat rejection rate was. So, we would just say, ‘Okay, we’re going to put one heat transfer coefficient in the whole water jacket. And we’re going to tune that based upon the heat rejection.’, So that’s what we were doing. He was getting a lot of criticism saying, ‘Aw, you can’t, that’s not right. It’s not constant everywhere.’, so we put our heads together and kept saying, ‘What are we gonna do? What are we gonna do? What are we gonna do?’.”

“I stuck my hand up and I said, ‘I think we could probably use CFD to get us some heat transfer coeffi cients that are not uniform.’, and so we started trying to do that,” says Bill Wheeler. “We did get some heat transfer coefficients out of those early CFD simulations. I don’t think they were very good but they were not uniform. We applied those to the stress model. Again, we tuned them up and down until we got the right heat rejection and kind of satisfi ed that. But in the interim, the people in the car companies, especially Ford, go, ‘Oh, wow. You can actually see where the flow is.’, which they were having a hard time visualizing back in the early ‘80s. This was probably 1983, we were doing this. And they started giving us contracts just to run the flow solutions without doing the heat transfer stuff in the blocks and stuff. And that’s really where adapco started doing CFD on an engineering services business, it was one of the first computer aided design tools that I think was universally adopted by an entire industry.”

More around this topic...

In the same section

© HPC Today 2024 - All rights reserved.

Thank you for reading HPC Today.