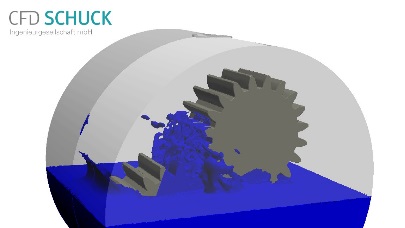

Although some of these configurations provided lower direct thermal loading, Thermacore engineers needed to demonstrate that asymmetries in thermal loading would not lead to local “hot spots” that might generate additional buoyancy-driven flow patterns (the potential source of a “self-induced seeing” problem). Using CD-adapco’s STAR-CCM+, the Thermacore engineers were not only able to fulfill the design criteria demonstrating that the surface temperature of the reflector could be kept below 10°C above ambient, but they also demonstrated that the criteria was sensible by visualizing the flow patterns generated within the enclosure as a result of natural convection.

The Thermacore team also examined the influence of various atmospheric wind loading scenarios, predicting flow patterns and heat transfer across a range of possible flow orientations, demonstrating that surface temperatures and turbulence levels would not exceed design criteria.

About Thermacore

Founded in 1970, Thermacore specializes in the custom design, development, and manufacturing of innovative, high performance thermal management and material solutions. Thermacore’s thermal management solutions can be found at both the system and component levels for a variety of OEM applications in the Military/Aerospace, Computer, Communications, Industrial, Government, and Medical/Test Equipment markets.

Thermacore’s thermal management technologies include: k-Core encapsulated Annealed Pyrolytic Graphite (APG) based solid conduction heat spreader assemblies and thermal straps (all metal and k-Core based); passive two-phase devices such as heat pipe assemblies, vapor chamber assemblies, thermal ground planes, loop heat pipes, extreme temperature heat pipes, CCHP and VCHP Spacecraft heat pipes, and more; liquid cooled cold plates; aluminum vacuum brazed assemblies, cold plates, heat exchangers, chassis; pumped single and two-phase liquid systems; Intelligent Thermal Management Systems (iTMS); rugged liquid cooling systems (rLCS™); and enclosure heat exchangers. Other unique capabilities include the ability to develop custom refractory metal alloys, cryomilled aluminum and magnesium, and material characterization and testing services.

Thermacore employs more than 175 employees at 5 facilities located in the United States (Lancaster, Pennsylvania; Langhorne, PA, and Ronkonkoma, NY; Pittsburgh, PA) and the United Kingdom (Ashington, Northumberland).

More around this topic...

In the same section

© HPC Today 2024 - All rights reserved.

Thank you for reading HPC Today.