Back on land, Fahrenthold and graduate student Moss Shimek extended this hybrid method in order to study the impact of projectiles on body armor materials in research supported by the Office of Naval Research. The numerical technique originally developed to study impacts on spacecraft worked well for a completely different application at lower velocities, in part because some of the same materials used on spacecraft for orbital debris protection, such as Kevlar, are also used in body armor.

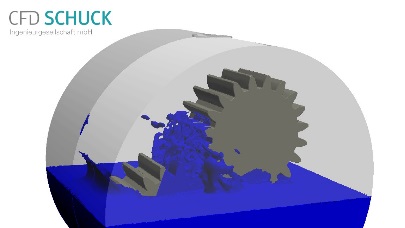

According to Fahrenthold, this method offers a fundamentally new way of simulating fabric impacts, which have been modeled with conventional finite element methods for more than 20 years. The model parameters used in the simulation, such as the material’s strength, flexibility, and thermal properties, are provided by experimentalists. The supercomputer simulations then replicate the physics of projectile impact and yarn fracture, and capture the complex interaction of the multiple layers of a fabric protection system — some fragments getting caught in the mesh of yarns, others breaking through the layers and perforating the barrier. “Using a hybrid technique for fabric modeling works well,” Fahrenthold says. “When the fabric barrier is hit at very high velocities, as in spacecraft shielding, it’s a shock-type impact and the thermal properties are important as well as the mechanical ones.”

Moss Shimek’s dissertation research added a new wrinkle to the fabric model by representing the various weaves used in the manufacture of Kevlar and ultra-high molecular weight polyethylene (another leading protective material) barriers, including harness-satin, basket, and twill weaves. Each weave type has advantages and disadvantages when used in body armor designed to protect military and police personnel. Layering the different weaves, many believe, can provide improved protection. Fahrenthold and Shimek (currently a post-doctoral research associate at Los Alamos National Laboratory) explored the performance of various weave types using both experiments and simulations. In the November 2012 issue of the AIAA Journal, they showed that in some cases the weave type of the fabric material can greatly influence fabric barrier performance. According to Shimek, “Currently, body armor normally uses the plain weave, but research has shown that different weaves that are more flexible might be better, for example in extremity protection.” Shimek and Fahrenthold used the same numerical method employed for the NASA simulations to model a series of experiments on layered Kevlar materials, showing that their simulation results were within 15 percent of the experimental outcomes.

“Future body armor designs may vary the weave type through a Kevlar stack,” Shimek said. “Maybe one weave type is better at dealing with small fragments, while others perform better for larger fragments. Our results suggest that you can use simulation to assist the designer in developing a fragment barrier which can capitalize on those differences.”

What can researchers learn about the layer-to-layer impact response of a fabric barrier through simulation? Can body armor be improved by varying the weave type of the many layers in a typical fabric barrier? Can simulation assist the design engineer in developing orbital debris shields that better protect spacecraft? The range of engineering design questions is endless, and computer simulations can play an important role in the ‘faster, better, cheaper’ development of improved impact protection systems. “We are trying to make fundamental improvements in numerical algorithms, and validate those algorithms against experiment,” Fahrenthold concludes. “This can provide improved tools for engineering design, and allow simulation-based research to contribute in areas where experiments are very difficult to do or very expensive.”

More around this topic...

© HPC Today 2024 - All rights reserved.

Thank you for reading HPC Today.